Shafts 101

Gary Mayes, Equip2Golf, Inc.

Shafts are often the most overlooked component of a golf club when selecting new equipment. Distance, accuracy and ball flight are all largely dependent on the club's shaft. Therefore it is imperative for all golfers to have a basic understanding of shaft characteristics and how they impact performance.

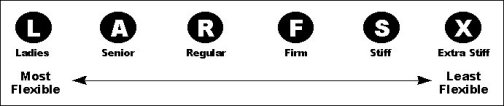

Flex. The most important factor in selecting a shaft is flex. Flex is basically the shaft's degree of bending and is usually indicated on a label on the shaft with one of several ratings. Most, but not all, manufacturers use the following ratings:

| Some manufacturers use a number system. For example, Royal Precision rates their Rifle series shafts from 2.0 to 8.0 offering sixty choices as opposed to the six mentioned above. This allows a more precise selection of flex to match the golfer's swing. Keep in mind that one manufacturer's "regular" flex rating may not be necessarily the same as the next manufacturer's "regular" flex rating. |  |

In order to compare flexes between manufacturers, the shaft's frequency needs to be measured. Frequency is the number of cycles per minute (CPM) or vibrations that the shaft has when the tip end is tweaked while the butt end of the shaft is firmly held at 5.25" from the butt end. A machine called a frequency analyzer is used to measure the shaft's CPM rating. The higher the CPM measurement, the stiffer the shaft is.

Generally speaking, a golfer using a shaft that is too flexible will have tendency to hook the ball while a golfer using a shaft that is too stiff will have tendancy to fade or slice the ball. The rule of thumb is a golfer wants the most flexible shaft that they can control. This would provide the greatest distance.

The best way to get properly fit for shaft flex is to receive assistance from a PGA professional or an accredited clubmaker. Try and test as many different flexes as possible prior to making a selection. Additional characteristics that affect performance are shaft material, kick point, and torque.

Shaft Material. Also important in selecting shafts is the material the shaft is made from. The most popular materials used in shafts today are steel and graphite. Shafts also come in titanium although they are not as widely accepted. Both steel and graphite have specific characteristics and advantages. Steel is an isotropic material meaning that it's molecular structure is uniform throughout. This structure allows manufacturers to produce shafts consistently which is the biggest benefit of steel. Steel shafts are also relatively inexpensive and heavier than graphite. Typical cost of a steel shaft is about $5-6 each with its weight usually in the 125-128 grams range (True Temper Dynamic Gold series) and can be as light as 89 grams (True Temper TrueLite series).

Graphite shafts are significantly lighter than steel typically weighing in the 55-60 grams range allowing design of longer clubs while maintaining swingweight. Graphite shafts are more expensive than steel with costs ranging from $10-100 per shaft. Graphite is touted for it's vibration dampening benefit, but recent advances in steel shafts (Sims' Shock Relief, True Temper's Sensicore, Ping's Cushin) have narrowed the gap between the two materials regarding this benefit. Graphite is less consistent than steel due to its complicated manufacturing process. Graphite shafts are made from graphite fibers (~2/3) held together by epoxy resin (~1/3). Weight is the biggest difference between the two with each having advantages depending on the golfer's need and preferences.

Kickpoint. Kick point, also known as flex point, refers to the specific point on a shaft where most of the flex occurs. Shafts are typically available with low, mid, or high kick points. In general the following characteristics apply:

A shaft designed with a low kick point usually is easier to control and provides a higher ball flight but with less distance. These shafts are often put into "game improvement" clubs appealing to higher handicap golfers. A shaft with a mid kick point provides a combination of power and accuracy with a medium ball flight. A shaft designed with a high kick point usually is more difficult to control and provides a lower ball flight but with more distance. These shafts are often put into "players clubs" preferred by lower handicap golfers.

Torque. Torque refers to the slight twisting movement of the shaft that occurs at impact. Torque is measured in degrees. The higher the torque rating the more the clubhead will twist at impact and thus slightly less control of the shot. Conversely, the lower the torque rating, the less the clubhead will twist at impact and slightly more control of the shot. Graphite shafts usually have a wider range of torque than does steel shafts, therefore consider the torque value when selecting graphite shafts.

Bottom Line. Be informed when selecting the most important component of your golf equipment. Pay particular attention to shaft flex trying as many different flexes as possible to ensure a proper fit. Assess the benefits of steel vs. graphite with respect to your overall game and needs. Kick point and torque are also characteristics to be considered although to a lesser degree than flex and shaft material. For additional assistance in selecting shafts that fit your game, see your local PGA professional or an accredited clubmaker.